Elexes offers a wide range of EMS services, from design and prototyping to electronic board production and advanced test solutions. With an efficient supply chain and 4.0 digitalization, we guarantee quality, innovation, and traceability for our customers in the IoT, telecommunications, and industrial sectors.

Prototyping

Production

Testing

Services

Engineering and

Technological Services

Aftermarket

Customer Service

Logistics

Our company capabilities include the development, design and support of new products. Our expertise also extends to improving prototypes or existing products that require in-depth manufacturing technical review and the introduction of improvements and innovations.

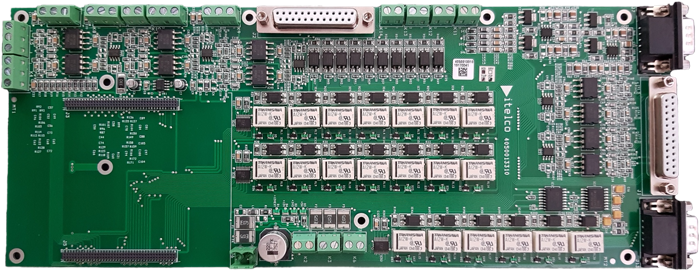

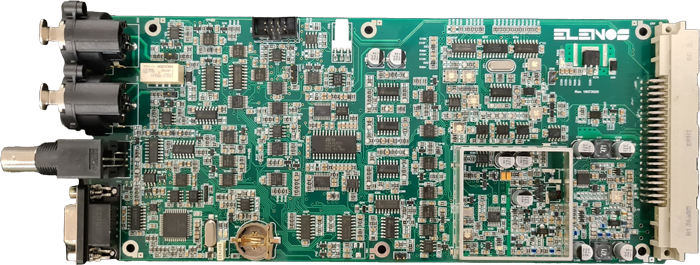

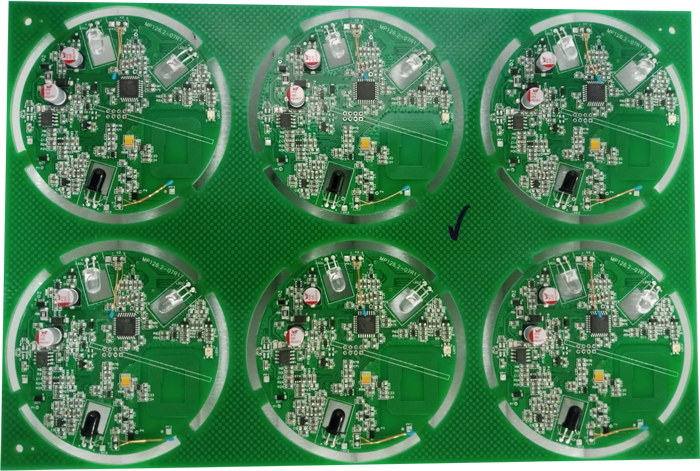

We provide production services for electronic boards of all technologies and levels of complexity. We handle the assembly of electronic components, offering customizations and specific configurations up to shipping complete, configured products to end users. Our solutions are available in consignment or turnkey modes.

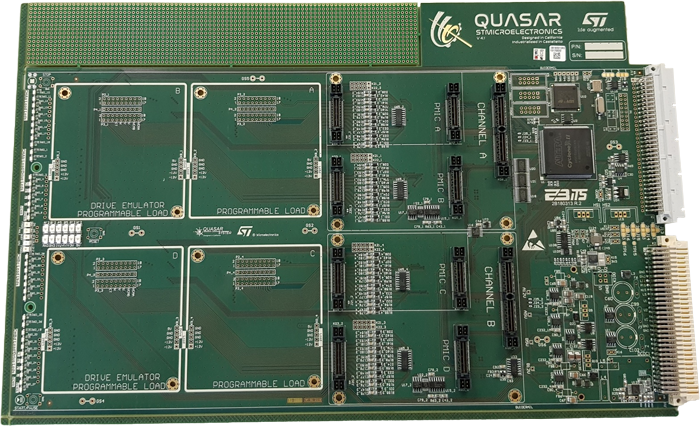

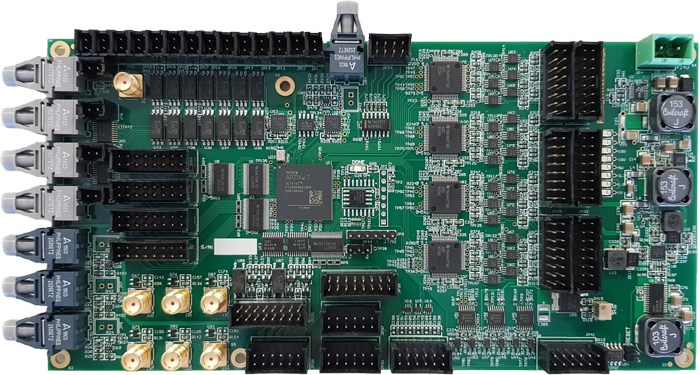

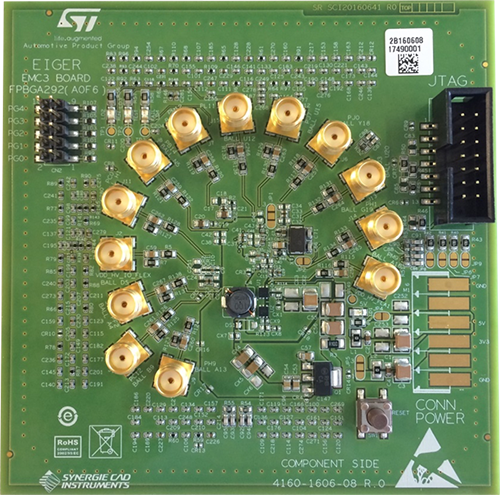

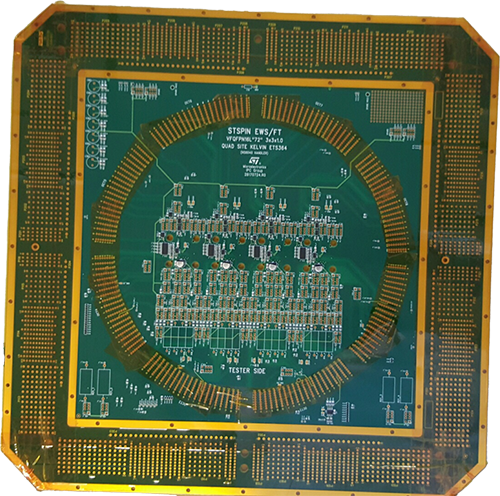

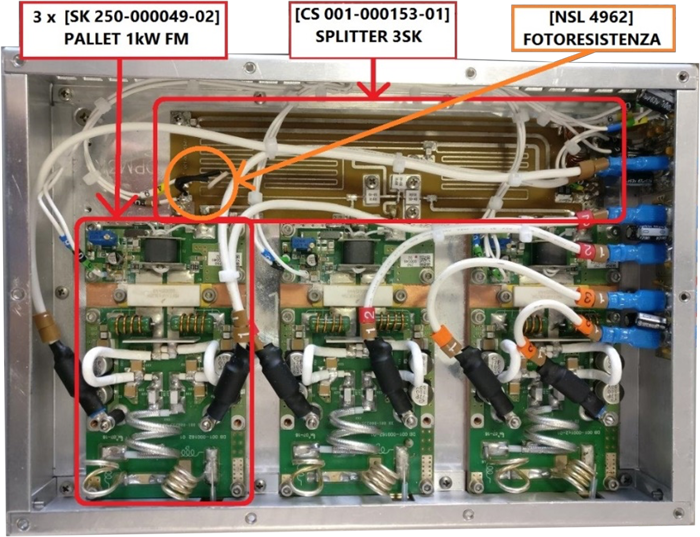

From personalized test strategy to the implementation of advanced testing solutions such as Flying Probe, In-Circuit, Boundary Scan, and functional tests. Test benches are custom-designed, following the functional specifications provided by the customer, optimizing ergonomic, aesthetic, and connectivity aspects to existing systems, aligning with Industry 4.0 principles.

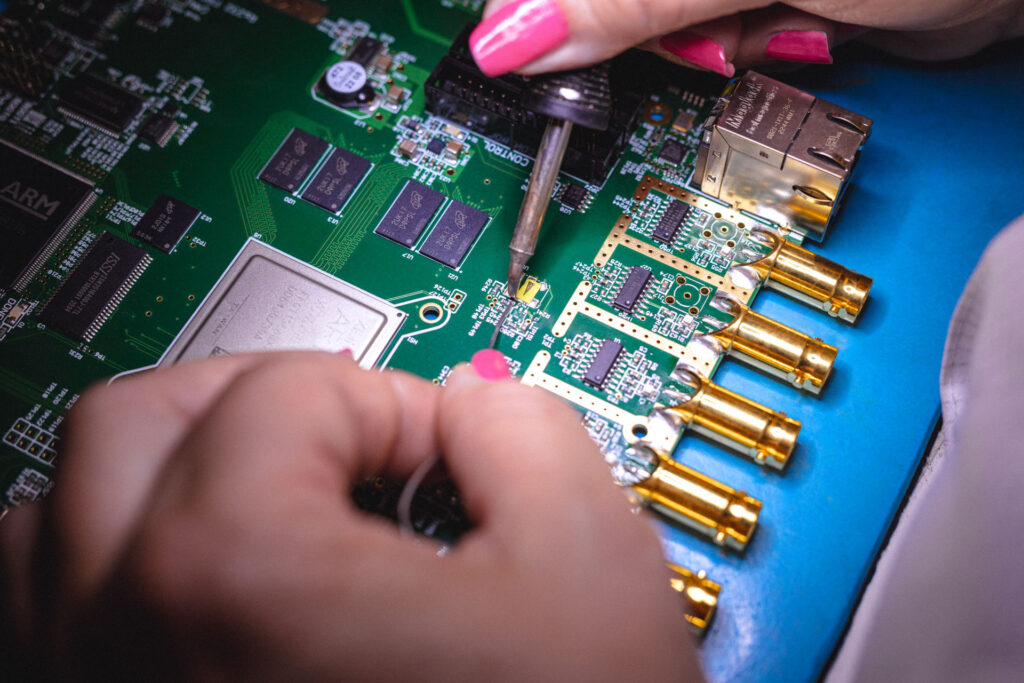

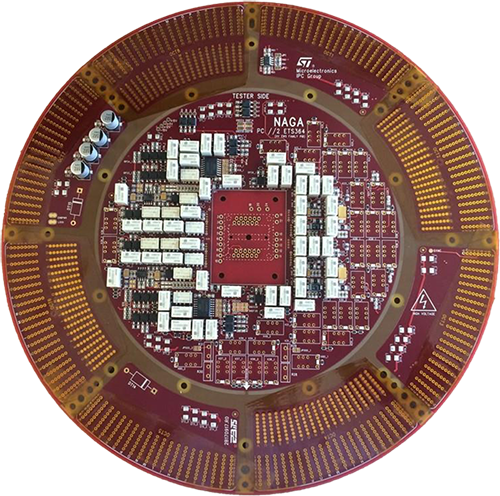

We have advanced skills in working on electronic boards to repair malfunctions, perform product updates, or rework complex boards and components, including the operation of mounting or replacing large Ball Grid Arrays (BGAs). Warranty and Out-of-warranty management. Management of obsolete components and EOL.

Our team is at your disposal to respond to all your needs. Contact us to discover your customized solution.

Strategic management of the supply chain, through clear definition of roles and responsibilities in collaboration with our customers, is essential to maximizing value and optimizing the use of financial assets.

Flexible Business Model adapting to different needs (including consignment, turnkey, mixed approaches).

Advanced traceability and Floor Control systems, ensuring synchronization and shared information.

Warehouse management and control designed to ensure process efficiency and transparency.

Access to a wide network of distributors, brokers, and suppliers.

Speed and responsiveness.

Worldwide logistics, Reverse Logistic, and Configure to Order.

Prototype creation is based on agility, transparency and information sharing, flexibility, and execution precision. All phases are shared with the customer to optimize any tests and reworks. Moreover, with a First Article Report, we make this process functional for mass production:

1

Production of printed circuit boards (PCBs) and development tools within 2 working days.

2

Accelerated component procurement within 3 working days.

3

Thorough examination of technical documentation and Design for Excellence (DfX) analysis.

4

Decision on manual or automatic assembly process based on specific needs.

5

Automated Optical Inspection (AOI) and X-Ray, as well as electrical testing to ensure quality.

6

Partial shipping option to expedite delivery.

7

Issuing detailed reports and constructive feedback at the end of testing.

8

Completing the entire prototype development cycle in less than 5 working days.

Our IT infrastructure implements Cloud-based systems for company and production line management, as well as internal servers with weekly backup protocols for company documentation, operational data, and metrics. We also use cloud-based email services and guarantee VPN access for technicians and staff working remotely. In terms of cybersecurity, our IT architecture and process controls are designed to rigorously protect data, both our own and our clients’.

Our ERP software is customized for efficient management of:

Warehouse

Accounting

Goods receiving and shipping processes

Inventory, identified by customer, with options for turnkey and consignment

Production batch progress

We share company metrics through:

Shift reports outlining quality and issues encountered

Daily monitoring of performance and quality data

Daily check of production and shipping progress

Weekly review of budget, staffing activities, and production line scheduling

Weekly meetings for sales and customer status updates

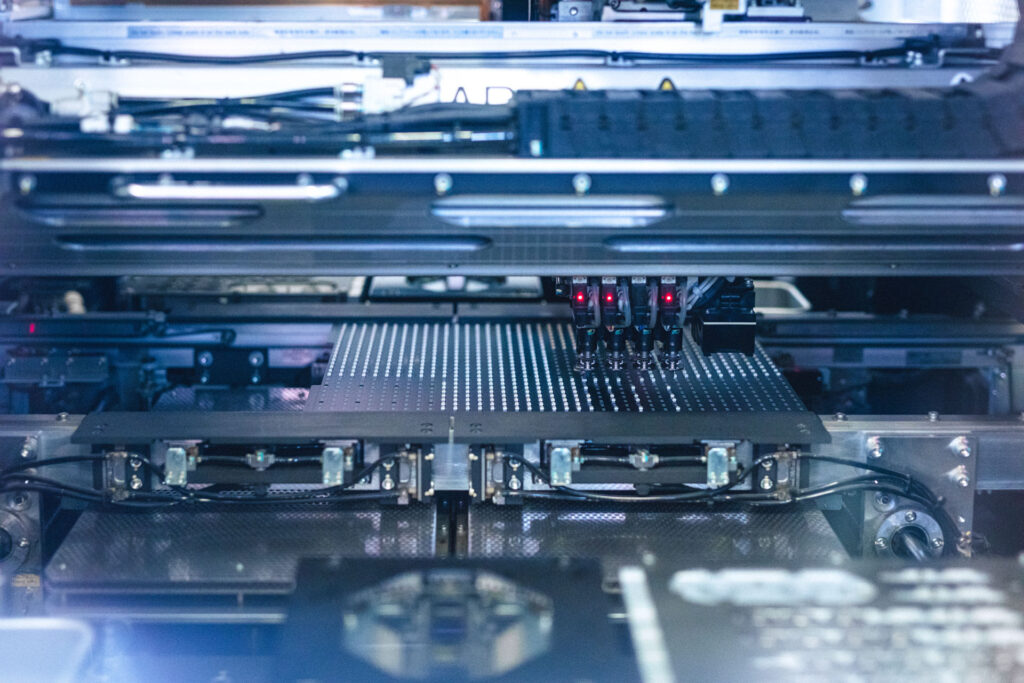

SMT Assembly (0201 – 01005 – PoP – uBGA – Flexy PCB)

2 Panasonic High Speed SMT Lines (> 200.000 componenti/ora)

3 Screen Printers

2 Reflow Ovens (nitrogen capability)

Baking & Re-packaging

THT Assembly

Selective Soldering in Nitrogen

Wave Soldering

Manual Soldering IPC Certified

ICT Flying Probe

Custom Functional Test (FCT)

Automated Optical Inspection (AOI)

X-Ray

Rework / BGA Rework

Prototypes and New Product Introduction

High Mix Low Volumes, High Volumes

Material Management, Kitting

Incoming Inspection and Warehouse Control

Mechanical Assemblies / Subassemblies

Traceability

Logistic & Fulfillment Services

Reverse Logistic & Aftermarket Services

Elexes’ expertise in managing processes for technical articles can be extended to any type of automated production line. This includes:

Qualification and maintenance of dedicated production lines.

Optimization of productivity parameters and KPIs.

Dedicated clean areas.

Complete traceability and trackability at lot and individual component level.

A traceability system easily accessible by customers.

Maintaining a clean and controlled environment in line with the requirements of the food, cosmetics, and medical sectors.

Elexes S.r.l.

Registered office

Via Cinque Martiri, 1

24029 Vertova (BG), Italy

VAT 01407750528

Operating headquarters

Via Fiume Po, 932

24040 Stezzano (BG), Italy